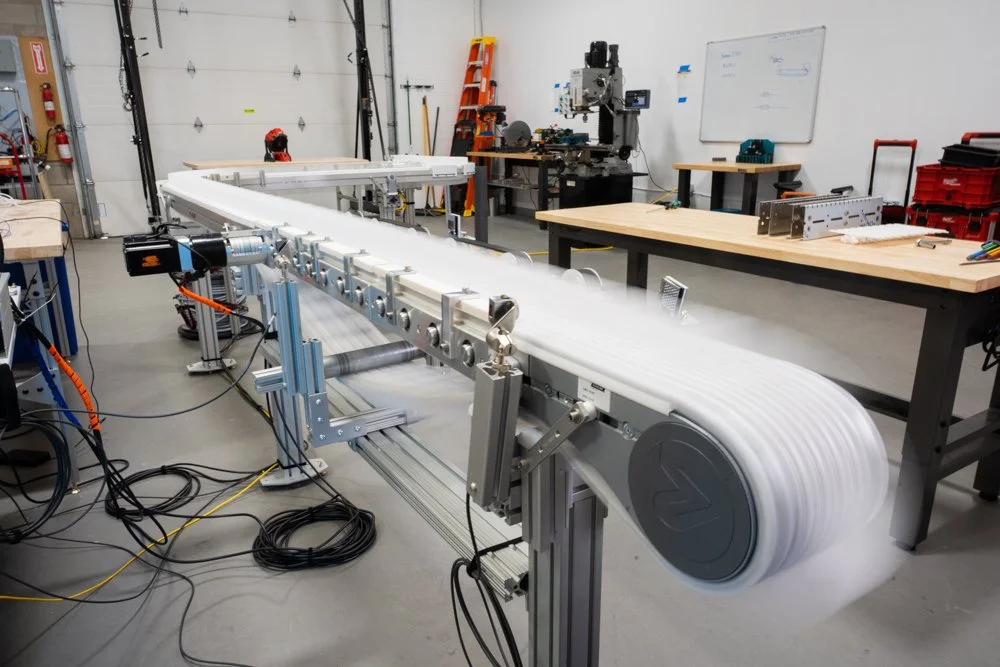

Synchronized flexible modular conveyor

Problem

A local food & beverage manufacturer required a flexible, modular conveyor to synchronously on-load and off-load product. Due to facility constraints, linear belt systems were not a feasible option for the application. With the asynchrony caused by belt stretch over time, traditional flexible modular conveyors were also not a suitable option. No standard conveyor solutions could support the requirements and many major conveyor manufacturers could not provide an alternative.

Solution

We designed, developed, built, and validated a proof-of-concept solution to support the application requirements, utilizing two custom timing belt assemblies at the head and tail of the conveyor and servo-powered drive technology. In-house durability and performance testing was completed to validate the overall synchronization concept, and also deliver a proposal for a full-production design with facility integration.

Custom timing belt synchronization assemblies

Full concept design & development

Integration of intelligent feedback sensors to confirm belt position accuracy and repeatability

In-house durability & performance testing

Minimal complexity build for efficient facility installation and scaling

Servo-powered to maintain precise motion profiles