Custom industrial production oven

Problem

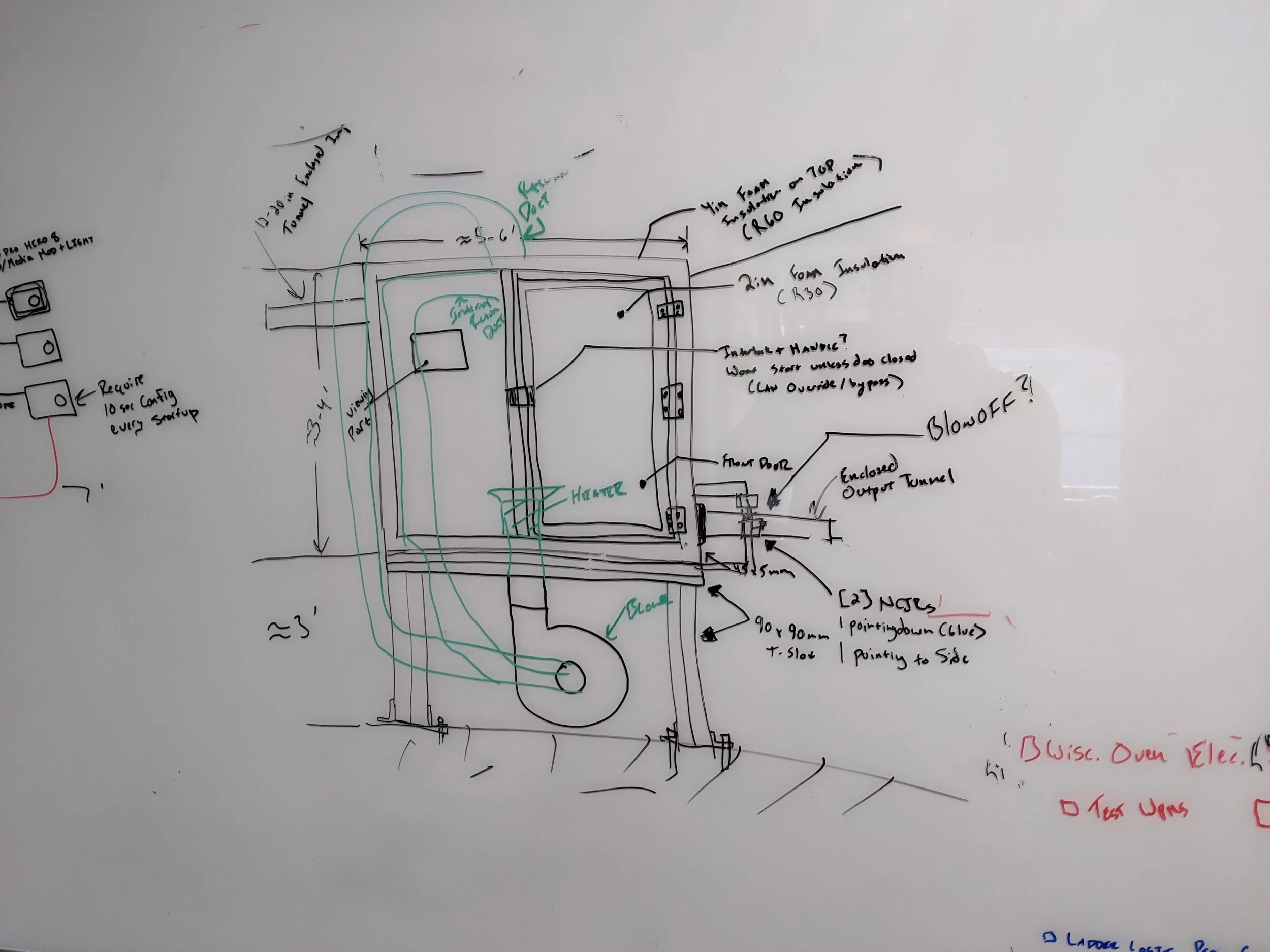

An in-line industrial oven for heating spout adhesive would not fit within new facility footprint requirements, requiring the 60’ linear oven to be reduced to a 7’x7’ footprint.

Solution

The Novum team designed, developed, built, and installed a custom switch-back oven for heating spouts in a 7’x7’ footprint, within a 5-month development timeline. The custom oven provides a reliable, safe, and robust solution utilizing carefully optimized facility floor space.

Integrated 3 Leister recirculating in-line 8kW heaters with 650 CFM blowers for fast startup and maximum heat transfer to spouts by forced-air convection

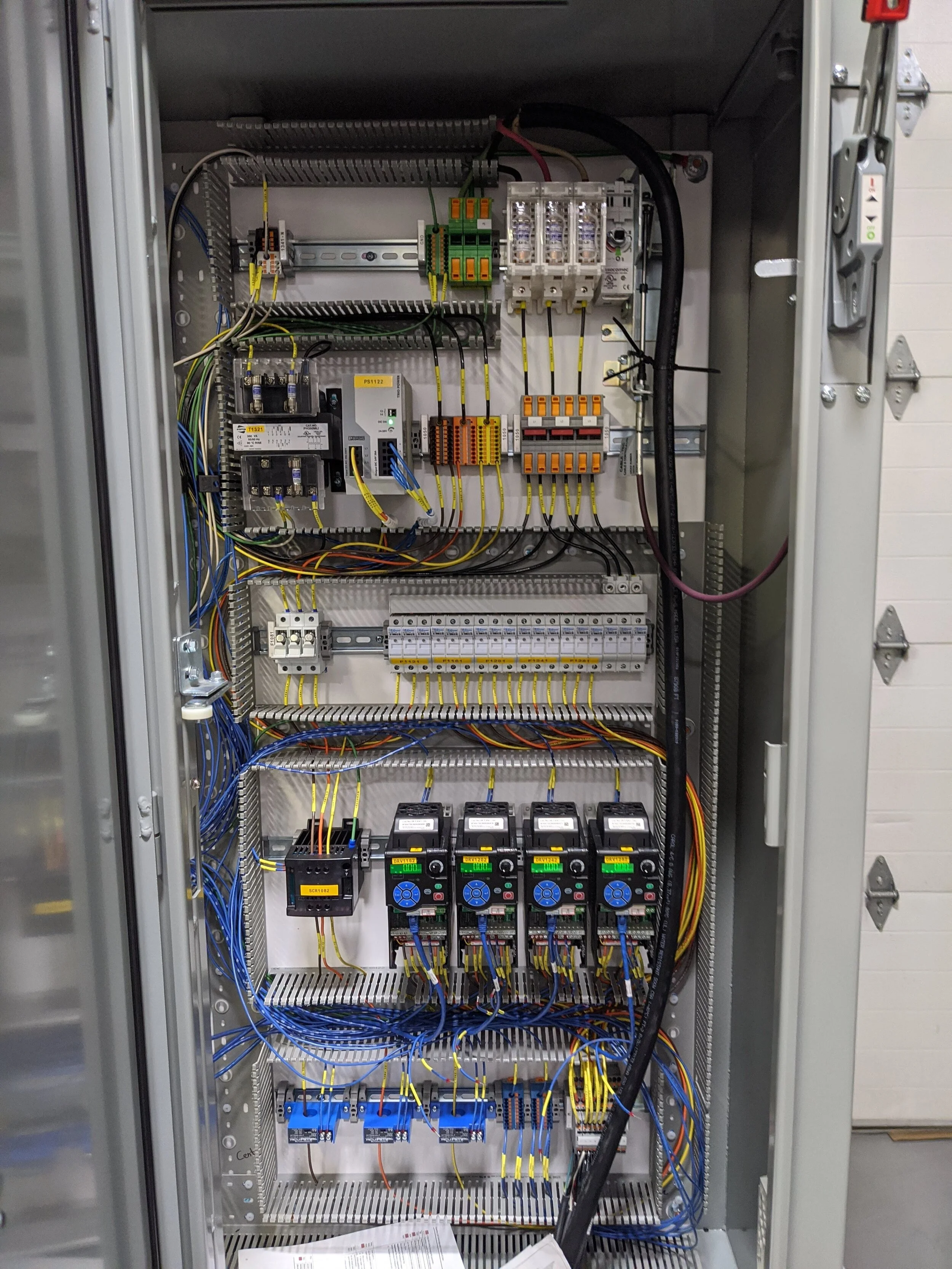

Integrated Phoenix Contact heavy-duty connectors for efficient cable management and on-site installation (main electrical enclosure to oven)

Installed local and remote HMI for multiple points-of-contact and operator visibility

Utilized highly insulating foam glass with custom stainless steel panel doors to minimize heat loss and maintain exterior surface temperature requirements

Developed oven structure from 80/20 aluminum t-slot, minimizing build and assembly time

Utilized Allen-Bradley Powerflex 525 AC drives with Safe Torque Off (STO) for reliable long-term control and safe operation

Incorporated multiple optical sensors for automated control